top load bottle test|pet bottle top load testing : solution Bottle Top Load Testing is a quality control measure that evaluates the maximum force a bottle cap or closure can withstand before it deforms or fails. It simulates real-world pressures experienced during storage, transportation, or .

Resultado da Moutinho Materiais para Construir, Novo Hamburgo. 10,660 likes · 20 talking about this · 1,260 were here. Para reformar, decorar e construir, você .

{plog:ftitle_list}

webDESGUACES EL BATAN (Cruz De La Gallina) 📍 Angel Guimera, Poligono Industrial Los Cascajos, nº 67, 35220, Las Palmas ¡Llámanos! Desguace de coches en Las Palmas. . Desguaces El Batán en Las Palmas dispone de un servicio de grúa y una amplia variedad de piezas y recambios para coches qué ofrecemos en nuestra web . Encontrarás el .

A top load test is a compression test on a product such as: drinks bottle, shampoo bottle, yogurt container, food tray, crate, etc. The axial force causes deformation of the product. Typically the test measures the maximum force to reach the yield point or a specified deflection distance.The ASTM D4169 top load test is a cornerstone method used to evaluate the performance of packaging under load. This guide provides an in-depth understanding of the test, its.

Top-load (or Column-crush) testing ensures that packaging products consistently meet the requirements for resisting the axial load exerted during: Production. Bottles, for example, must .In particular, a top load test was used on five partially filled bottles, which revealed a mechanical behavior articulated in different phases. As general results, it is possible to say that both models acceptably predicted the initial phases of .

The top load of several plastic bottles are tested using an FMS Series Force Measurement Machine and L2 PLUS Software by Starrett.Bottle Top Load Testing is a quality control measure that evaluates the maximum force a bottle cap or closure can withstand before it deforms or fails. It simulates real-world pressures experienced during storage, transportation, or .

A sample bottle, taken at regular intervals from each production line is placed directly beneath a 50 mm diameter compression plate and a compressive load applied at a rate of 250 mm/min until the bottle has visibly buckled. The AFG records the maximum load experienced during the test and displays this result on its clear, digital screen. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

Top load testing can accurately determine the strength and capability of the sample, helping manufacturers deliver PET containers that assure safe product delivery. What Is Top Load Testing. Top load testing is a functional test that helps manufacturers or Users verify PET bottle seal and holding capacity.

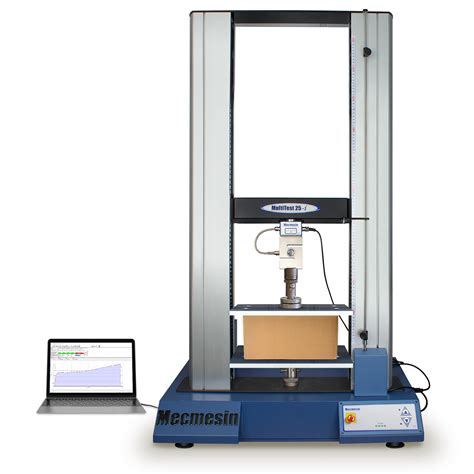

Top-load testing (also known as 'column-crush' and 'axial force resistance') is performed mainly on blow moulded, thermoformed or injection moulded plastic containers. It measures the compressive strength of such containers to ensure they do not deform or break when subjected to axial forces during the processes of filling, closure, storage and transport. There is an ever .MultiTest-dv with AFG top-load bottle test application . . The most popular model in the -dV range for top-load testing is the 2.5kN version and it is most commonly used with AFG's of capacity 500N (110 lbf), 1000N (220 lbf) or 2500N (550 lbf). Compatible with top-load compression plates (vented and non-vented). .PTI offers over fourteen different tests for preform and bottle testing including burst pressure, density, dimensions, and more. X. . Top Load. To ensure that the vertical strength of PET bottles is sufficient to meet minimum performance standards for vertical loading as might be encountered during bottle filling, capping and stacking of .Thus, to achieve this requirement the manufacturers take the test of each and every aspect of the material. Thus they make use of various machines including a top load tester to test if the bottles will remain safe by adding top load. Here in this blog, we are going to discuss the features of the digital top-load testing instrument from Presto.

Top-load plastic bottle test in factory by semi-automated process. Top-load plastic bottle testing systems in factory conditions and QC lab. Touchscreen operation provides a standalone solution with pre-programmed routines. Adding software for data capture and subsequent analysis enables SPC to control production .

variability across test administrations impact

top load testing process

In case of failure of the top load test, the PET bottle design should be reconsidered. Top load test determines the weak points in the bottles when the bottle falls freely carrying weight. Apart from that, this test detects the flaws in blow moulding line if buckling is repeated occurring on the same point. Downgauging is much in trend due to . Bottle top load testing involves placing a bottle on a platform and gradually increasing the weight applied to the top of the bottle until it deforms or breaks. The testing machine applies the weight slowly and continuously, simulating the stresses the bottle would experience during transportation and storage.

Test standards commonly used. ISBT and CETIE Voluntary Test methods for PET bottles Coca-Cola SM-PR-2645 Vertical Load Resistance for non-refillable Plastic Bottles ISO 3037 Corrugated fibreboard - determination of edgewise crush resistance (unwaxed edge method) ISO 8113 Glass containers - resistance to vertical load - test method ISO 12048 Packaging - .Specifically designed for testing plastic bottles; Adjustable topload compression speed and range; Numeric and graphic reporting capabilities; . semi-automated laboratory devices for top load, pressure and volume plus Agr’s Gawis . Top-load testing solutions Top-load crush test of plastic bottles. 18 February 2021 Solution. Software-controlled test stand; Selection of compression plate accessories; Benefits. Product quality testing to internal .

The crush load goes beyond the top load simulation, and continues the calculation where the top load stops. Normally the top load analysis shows the force versus displacement graph, and at the point the force is decreasing, the .

Top Load Testing of PET Bottles. Top load testing is a method that simulates how a bottle or container is compressed under a top load. The equipment helps to create the actual-life compression force a pet bottle can tolerate during warehousing, storage or in the transportation. This test also helps the user to examine the capacity of a bottle .VP-1000 PET Bottle Vertical / Top Load Tester is professionally designed to test the top load resistance, top load-deformation, crushing compressive force of PET bottle or container of package.. The results could be used to guide, control and improve the product quality. Product Features. Customized test mode can be realized according to user needs to meet various test . Since all the induced mechanical properties exhibit dispersions, a probabilistic description of the orthotropic behavior law is managed and a stochastic simulation of the top load test is performed in order to define a confidence region for the bottle performance.

Presto Stantest offers a wide range of Top Load testers to test the top load strength of the bottles. The testing instruments are intended as per the standards provided by reputed organizations such as ASTM. Specifications of Presto’s Range of Top Load Testers.It is widely used to test the maximum amount of load that a bottle can bear to its maximum when increasing amount of force is applied to the PET products. The test also helps to measure the compressive strength and bursting strength of the bottles. . In a top load test, the test sample us placed in the jaws of the machines and constant amount .

The top load tester machine will display the maximum load or force exerted on the PET bottle during the test. Record this value for each bottle tested. Tips To Perform The Top Load Test Accurately. Perform the top load test on multiple PET bottles from your sample to ensure consistency and reliability of the results.

PET bottle top-load test using a 2.5 kN (550 lbf) digital motorised MultiTest-d test stand combined with a digital Advanced Force Gauge (AFG).Beverage can top-load test using a 10 kN (2200 lbf) touch-screen MultiTest-xt twin-column system.PET bottle test using a 5 kN (1100 lbf) touch screen MultiTest 5-xt system. Bottle cages come in top load and side load versions, and what’s best for you will depend on your frame. If there is tons of room in your front triangle, a top load cage will work just fine. . How we test the best MTB bottle cages. All the bottle cages tested here have been used during several months of riding on various bikes, over .

top load testing machine

The BTLT-2 Glass Bottle Top Load Tester is designed to measure the maximum resistance of glass bottles to top load pressure. This instrument is essential for the glass container industry, providing manufacturers with critical data to maintain or . The most focused test process in the Bottle packaging industry is the Top Load testing of PET bottles. The bottles due to its demand in various industries for packaging products experience the top load issue. So, it is a vital test to be performed on the bottle’s resistance capability against prolonging buckling load to check quality control.

variables that impact test scores

28 de ago. de 2021 · We have 5 user reviews for the phone number +18882094086 / 8882094086 (landline phone, United States, non-geographic, Toll-Free). The number .

top load bottle test|pet bottle top load testing